Comprehensive asset management for mission-critical facilities is a complex balancing act requiring organizations to optimize resources while safeguarding against potential risks. Two primary methodologies, criticality analysis and risk analysis, offer valuable insights into asset performance and vulnerabilities. However, relying on more than one approach can lead to fragmented perspectives. Let’s explore the integration of both criticality analysis and risk analysis to achieve a holistic understanding of asset management, driving informed decision-making and resource allocation.

The Growing Need for Holistic Analysis in Comprehensive Asset Management

Utilization – Recent industry surveys have underscored the critical importance of maximizing asset utilization. Manufacturing sectors often operate at only 60% capacity, while buildings may fall below 33%. This chronic underutilization results in significant economic losses, with estimates surpassing $700 billion in the United States alone due to downtime and underperformance.

Maintenance – Although asset breakdowns may appear unpredictable, patterns in failure modes can offer valuable insights. Through evaluation and analysis, organizations can implement selective maintenance practices, optimize equipment sizing, and enhance redundancy measures to mitigate risks.

Criticality Analysis Demystified

Criticality analysis evaluates the consequences of asset failures across various metrics, including revenue, safety, compliance, and reputation. When experts assess the severity of impacts, they assign scores on a scale of 0 to 4. The higher ratings indicate the need for contingency planning to mitigate potential disruptions.

- Revenue and Productivity Losses: Production line failures or software crashes can result in significant revenue loss due to downtime. Costs can escalate rapidly, exceeding $100,000 per day for high-value equipment.

- Regulatory Non-Compliance: Violations of safety, emissions, or technical standards can lead to heavy penalties, surpassing seven figures.

- Damage to Reputation: Failure to meet performance guarantees can erode brand equity and hinder growth prospects.

- Cascading Secondary Failures: Initial breakdowns can trigger cascading shutdowns if surrounding equipment is exposed to unsafe conditions.

While qualitative, criticality analysis considers factors indicative of failure likelihood based on maintenance history, deterioration trends, and usage intensity.

Risk Analysis: A Probabilistic Perspective

Risk analysis adopts a probabilistic approach to reliability assessment, utilizing techniques to forecast vulnerabilities based on equipment failure histories and industry benchmarks. Key focus areas include:

- MTBF Benchmarks: Comparing mean time between failures with population averages provides insights into likelihood based on manufacturing quality, maintenance practices, and operating conditions.

- Lab Testing: Stress testing reveals deterioration rates under different conditions, informing predictive models.

- Asset Duty Cycling: Monitoring loading profiles relative to design maximums helps prevent premature failures.

Collecting clean data enables the creation of baseline failure likelihood models, allowing organizations to identify factors influencing equipment uptime.

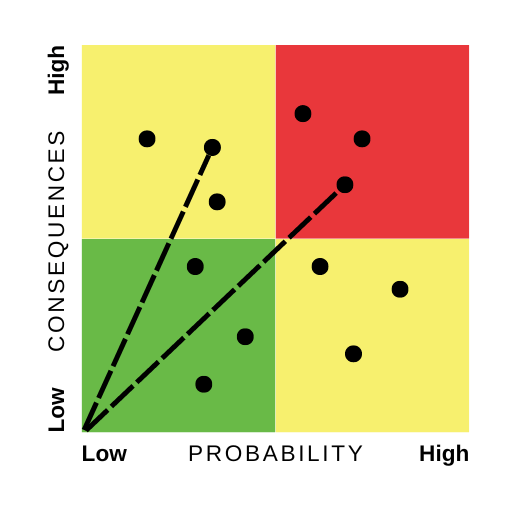

Reconciling Criticality & Risk

Criticality analysis highlights assets requiring contingency planning after failures, while risk analysis identifies vulnerabilities requiring preventive interventions beforehand.

Having a platform like MCIM lets you integrate these approaches for a comprehensive understanding of assets, guiding maintenance, capital planning, and resilience investments.

Integrating criticality and risk analysis offers a comprehensive approach to asset management, addressing the limitations of fragmented methodologies. By leveraging cross-pollinated insights, organizations can enhance operational efficiency and resilience, ensuring sustained success in dynamic environments.