Maintaining equipment and assets efficiently is crucial for operational success in facility management. As technology has advanced, maintenance strategies have evolved from reactive approaches to more sophisticated, proactive methodologies. Preventive Maintenance (PM), Condition-Based Maintenance (CBM), and Predictive Maintenance (PdM) are three key maintenance strategies we’ll delve into, highlighting their characteristics, benefits, and limitations to help facility managers make informed decisions about their maintenance approaches.

Preventive Maintenance: The Foundation of Proactive Facility Management

Preventive Maintenance (PM) – also Preventative Maintenance – is a proactive approach that involves regularly scheduled maintenance tasks performed on equipment and assets to prevent unexpected failures and extend their lifespan.

Key characteristics:

- Time-based or usage-based scheduling

- Routine inspections, cleaning, lubrication, and parts replacement

- Aims to reduce unplanned downtime and emergency repairs

Benefits:

- Increased equipment reliability and longevity

- Reduced risk of unexpected breakdowns

- Improved safety for personnel and operations

- Better budget planning and resource allocation

Limitations:

- Potential for over-maintenance

- May not account for actual equipment condition

- Can be labor-intensive, time-consuming, and expensive

Example: A facility manager schedules monthly inspections and quarterly oil changes for all HVAC units, regardless of their actual condition or usage.

Condition-Based Maintenance: Listening to Your Equipment

Condition-Based Maintenance (CBM) takes maintenance strategy a step further by basing decisions on the actual condition of the equipment and assets. This approach relies on real-time monitoring and data collection to determine when maintenance is necessary.

Key characteristics:

- Continuous or periodic monitoring of equipment condition

- Utilizes sensors, inspections, and performance data

- Maintenance performed when specific indicators show signs of decreasing performance or impending failure

Benefits:

- Reduced unnecessary maintenance activities

- Improved equipment reliability

- More efficient use of maintenance resources

- Early detection of potential issues

Limitations:

- Requires investment in monitoring equipment and technology

- May require specialized skills for data interpretation

- Not all failure modes can be easily monitored

Example: Vibration sensors on a critical pump trigger an alert when vibration levels exceed a predetermined threshold, prompting maintenance before failure occurs.

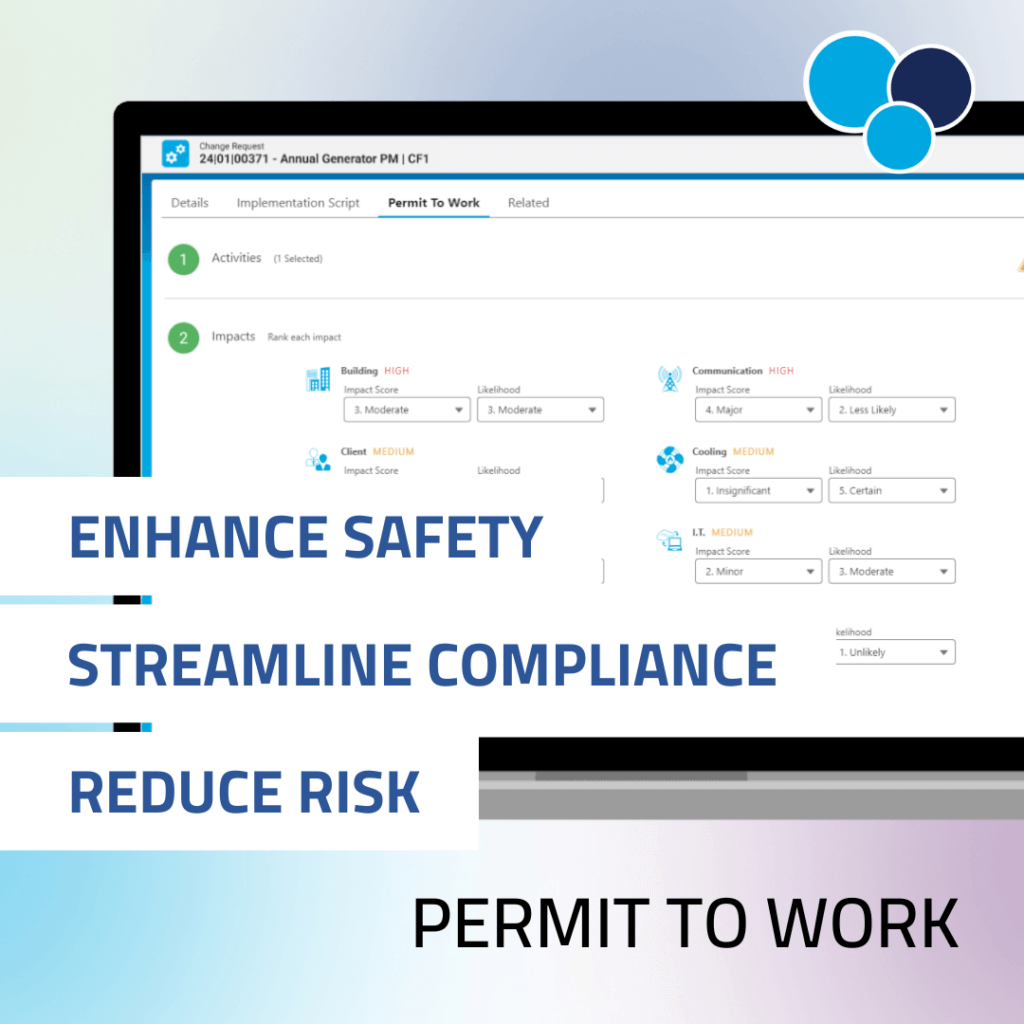

Predictive Maintenance: The Future of Facility Management

Predictive Maintenance (PdM) represents the cutting edge of maintenance strategies. It combines the principles of condition-based maintenance with advanced analytics, machine learning, and artificial intelligence to predict when equipment is likely to fail and prescribe appropriate maintenance actions.

Key characteristics:

- Utilizes historical and real-time data

- Employs advanced analytics and machine learning algorithms

- Predicts future equipment performance and potential failures

- Prescribes optimal maintenance actions and timing

Benefits:

- Maximized equipment uptime and reliability

- Optimized maintenance scheduling and resource allocation

- Reduced maintenance costs through precise interventions

- Supplies and parts ordered in advance, allowing inventory to reflect needs

- Enhanced ability to prevent catastrophic failures

Limitations:

- Requires investment in technology and expertise

- Depends on the quality and quantity of historical data

- May face challenges in implementation and cultural adoption

Example: A predictive maintenance system analyzes patterns in power consumption, temperature, and vibration data from a production line to forecast potential failures weeks in advance, allowing for planned interventions.

Comparative Analysis:

Data Requirements:

- Preventive Maintenance: Minimal data is required based on manufacturer recommendations and historical performance.

- Condition-Based Maintenance: Requires real-time or periodic condition monitoring data.

- Predictive Maintenance: Demands extensive historical and real-time data for accurate predictions.

Technological Complexity:

- Preventive Maintenance: Low complexity; can be managed with basic CMMS systems.

- Condition-Based Maintenance: Moderate complexity; requires sensor technology and data analysis tools.

- Predictive Maintenance: High complexity; involves advanced analytics, machine learning, and AI capabilities.

Cost Considerations:

- Preventive Maintenance: Lower initial costs but potential for unnecessary maintenance expenses.

- Condition-Based Maintenance: Moderate investment in monitoring equipment and software.

- Predictive Maintenance: High initial investment but potentially lowest long-term maintenance costs.

Maintenance Timing:

- Preventive Maintenance: Fixed schedules based on time or usage.

- Condition-Based Maintenance: Performed when conditions indicate the need.

- Predictive Maintenance: Optimally timed based on predictive analytics.

Failure Prevention:

- Preventive Maintenance: Reduces the likelihood of common failures.

- Condition-Based Maintenance: Addresses developing issues before failure occurs.

- Predictive Maintenance: Proactively predicts and prevents potential failures.

Implementing a Hybrid Approach:

While each maintenance strategy has merits, many facilities successfully implement a hybrid approach. This allows them to leverage the strengths of each plan based on the characteristics of and how critical different assets are:

Critical assets with high failure costs: Implement predictive maintenance for early detection and prevention of failures.

Assets with clear wear patterns: Apply condition-based maintenance to optimize maintenance timing.

Non-critical assets or those with minimal data: Utilize preventive maintenance for cost-effective upkeep.

Understanding the nuances of different maintenance strategies becomes crucial as facility management evolves. Preventive Maintenance provides a solid foundation for proactive upkeep, while Condition-Based Maintenance offers a more refined approach based on actual equipment health. Predictive Maintenance represents the cutting edge, leveraging advanced analytics to forecast and prevent failures.

The choice between these strategies—or a combination thereof—depends on various factors, including the nature of the facility, the criticality of assets, available resources, technological capabilities, and investment strategies. By carefully considering these factors and the characteristics of each maintenance approach, facility managers can develop a comprehensive strategy that optimizes reliability, reduces costs, and ensures peak operational performance.

As technology advances, more innovations can be expected that will make monitoring assets easier, data analysis automated, and help bring costs of new methods down, potentially blurring the lines between these approaches and offering even more sophisticated solutions for facility management challenges.