MCIM ensures that every asset in your facility operates at peak performance with cost-effective maintenance and energy strategies.

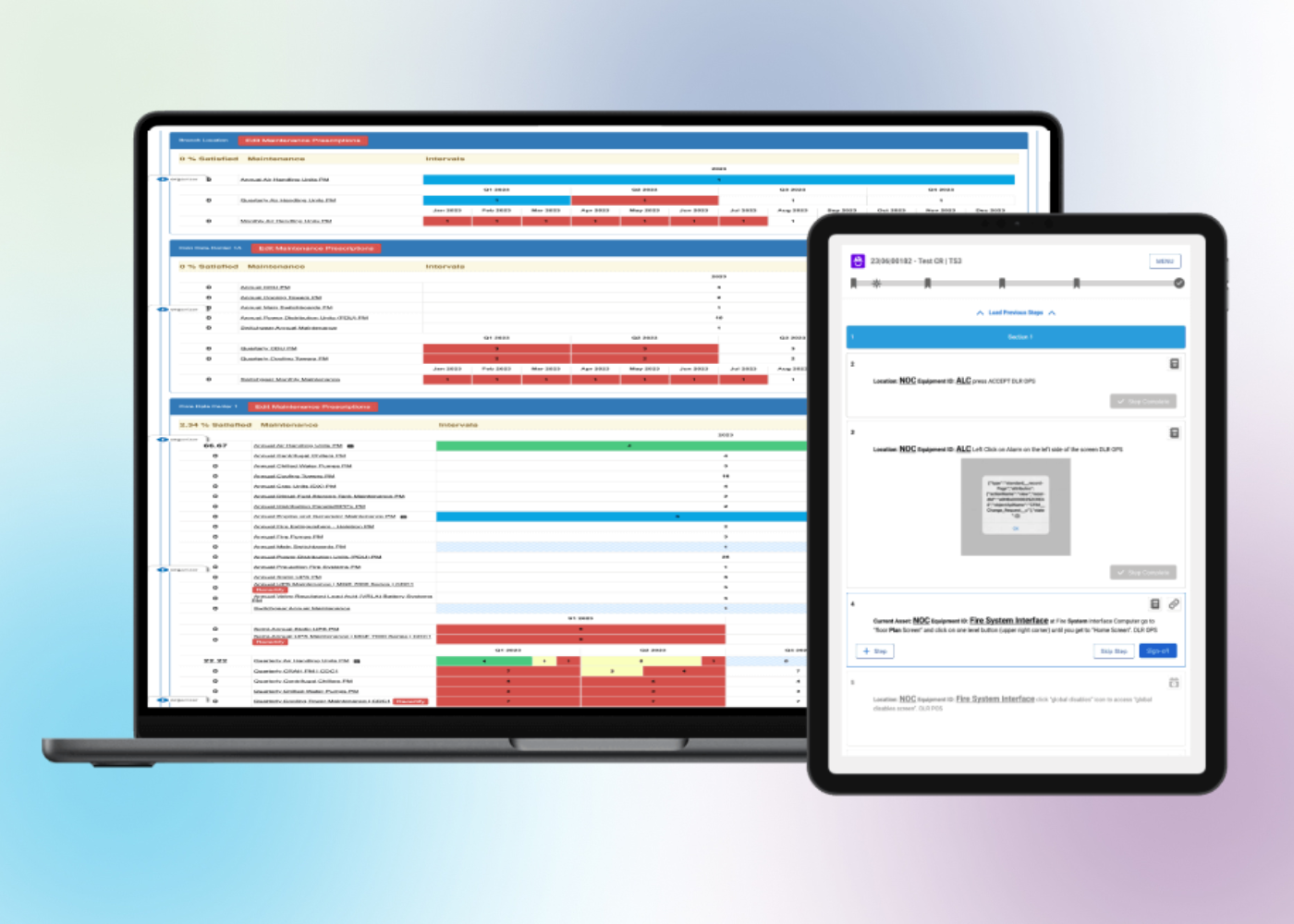

Smarter Maintenance for Maximum ROI

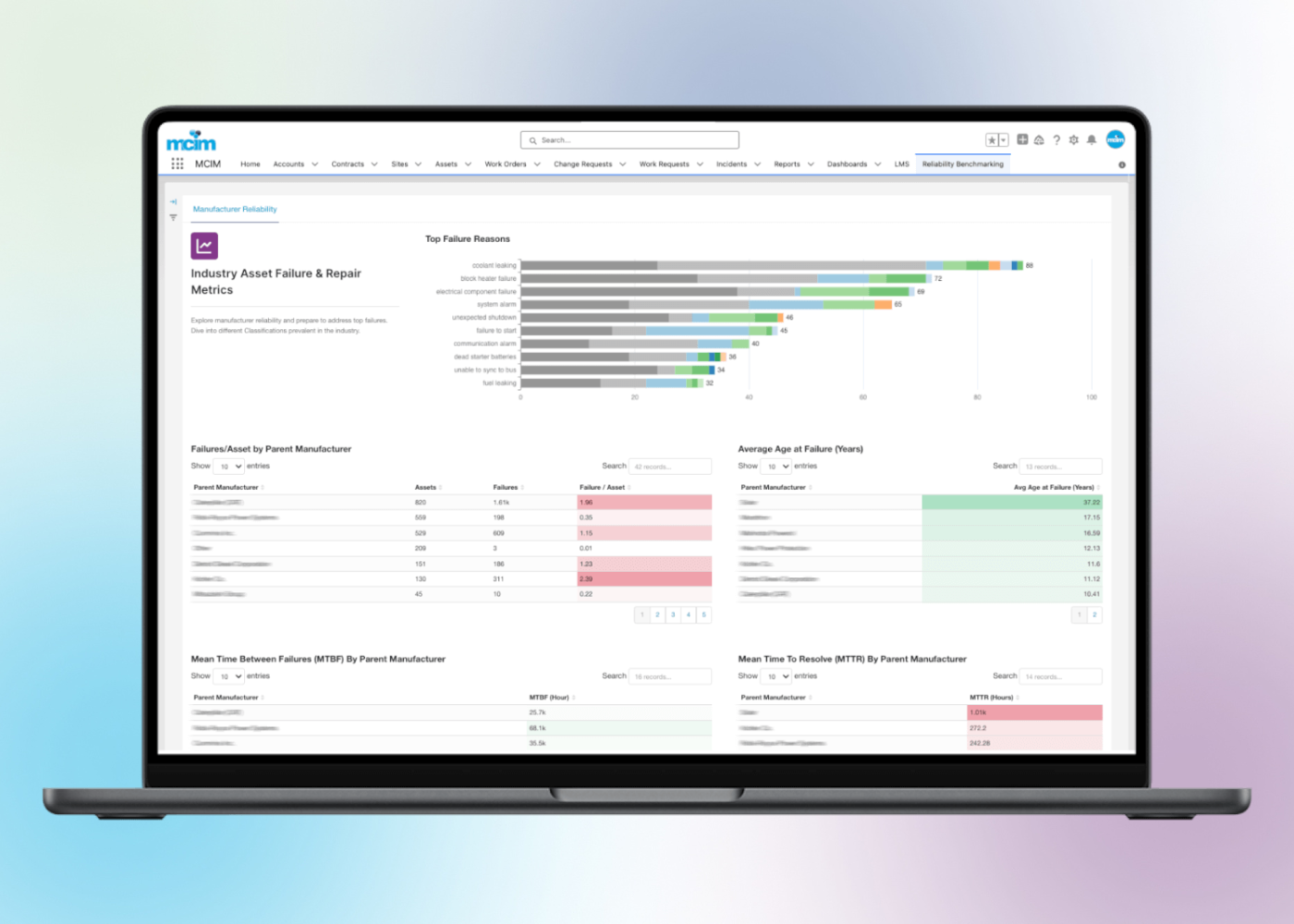

☑️ Vendor Performance & Cost Benchmarking: Track maintenance expenses and service quality to optimize vendor contracts and eliminate overpayments.

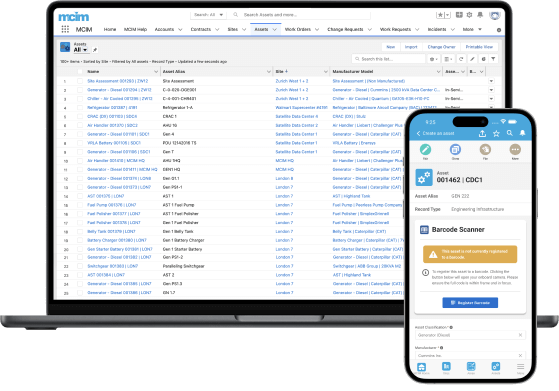

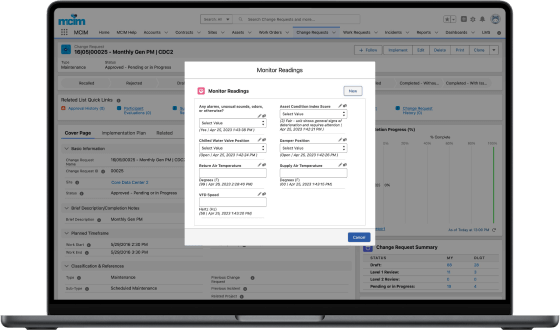

☑️ Intelligent Maintenance Strategies: Shift from time-based to predictive maintenance, using real-time asset data to prioritize servicing.

☑️ Portfolio-Wide Cost Optimization: Compare costs across locations to identify savings opportunities and improve budget efficiency.

☑️ Increase Equipment Reliability: Reduce unexpected failures and unplanned expenses.

Lower Costs Without Sacrificing Performance

☑️ Power Usage Effectiveness (PUE) Monitoring: Measure equipment-level power consumption and pinpoint inefficiencies.

☑️ Automated UPS Load Management: Optimize UPS capacity and failover thresholds for peak energy efficiency.

☑️ HVAC & Environmental Optimization: Implement data-driven controls for temperature and humidity to minimize energy waste.

☑️ Drive Sustainable Operations: Reduce carbon footprint while cutting operational expenses.

Actionable Insights for Smarter Investments

☑️ Data-Driven Vendor Selection: Leverage global cost and performance analytics to negotiate better contracts.

☑️ Predictive Service Adjustments: Adjust maintenance scopes based on real-time asset conditions to prevent over-servicing.

☑️ Smart Insourcing vs. Outsourcing: Identify which maintenance tasks can be handled in-house for better cost control.

☑️ Lower Maintenance Spend: Spend smarter with real-time data on service needs and costs.

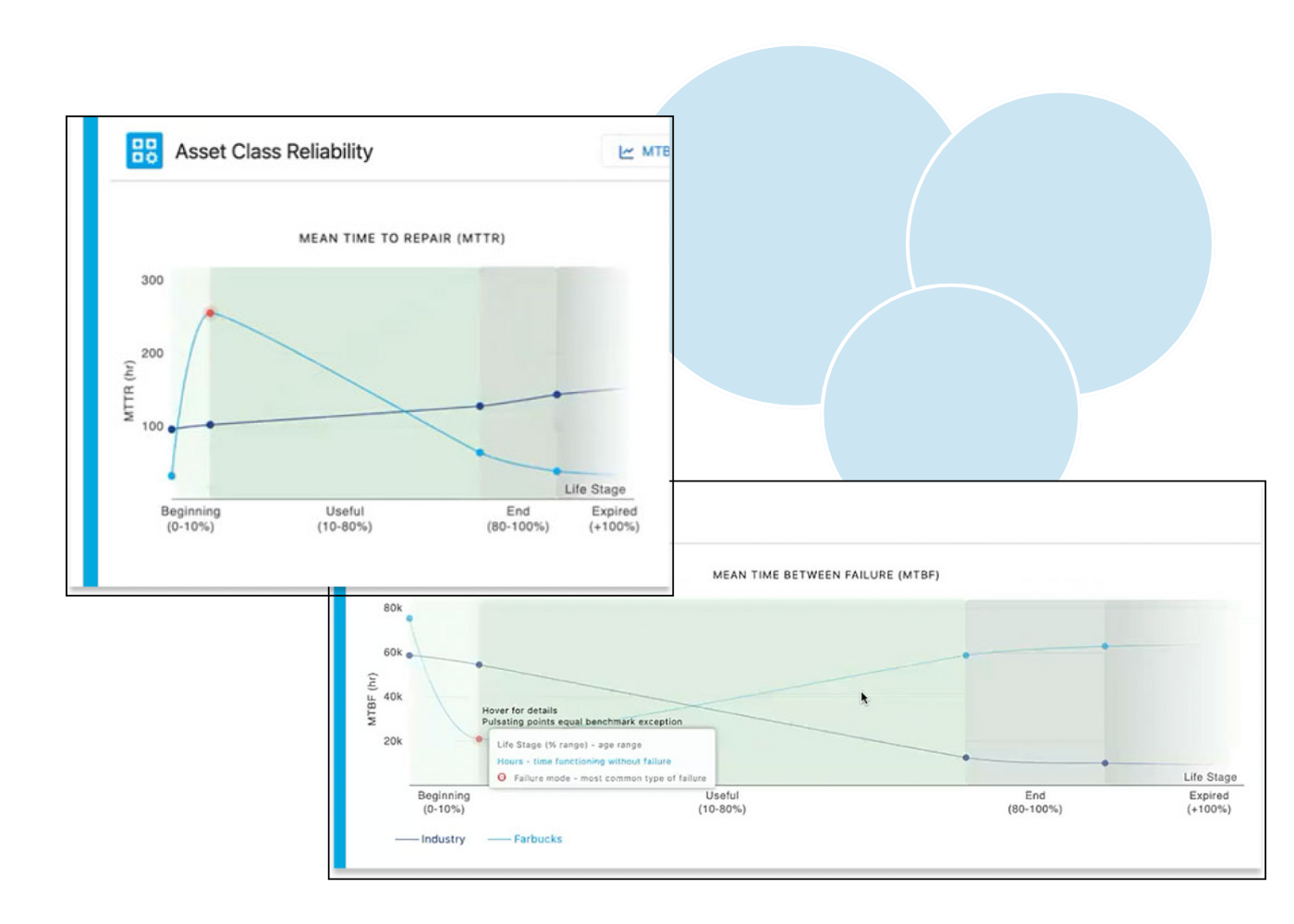

Stay Ahead of Equipment Failures Before They Happen

☑️ Automated Anomaly Detection: Identify performance deviations early with AI-driven monitoring and real-time alerts.

☑️ Asset Condition Index (ACI) Scoring: Track real-time asset health and prioritize maintenance based on risk levels.

☑️ Seamless Integration with BMS & DCIM: Connect equipment data to building and data center management systems for a holistic view.

⭐ Zero Downtime Strategy: Keep critical infrastructure running without unexpected failures.

Extend equipment lifespan and avoid unnecessary servicing.

Cut power waste and improve sustainability.

Identify savings across your portfolio.

Reduce costs, increase uptime, and optimize energy use with a smarter approach to asset performance.