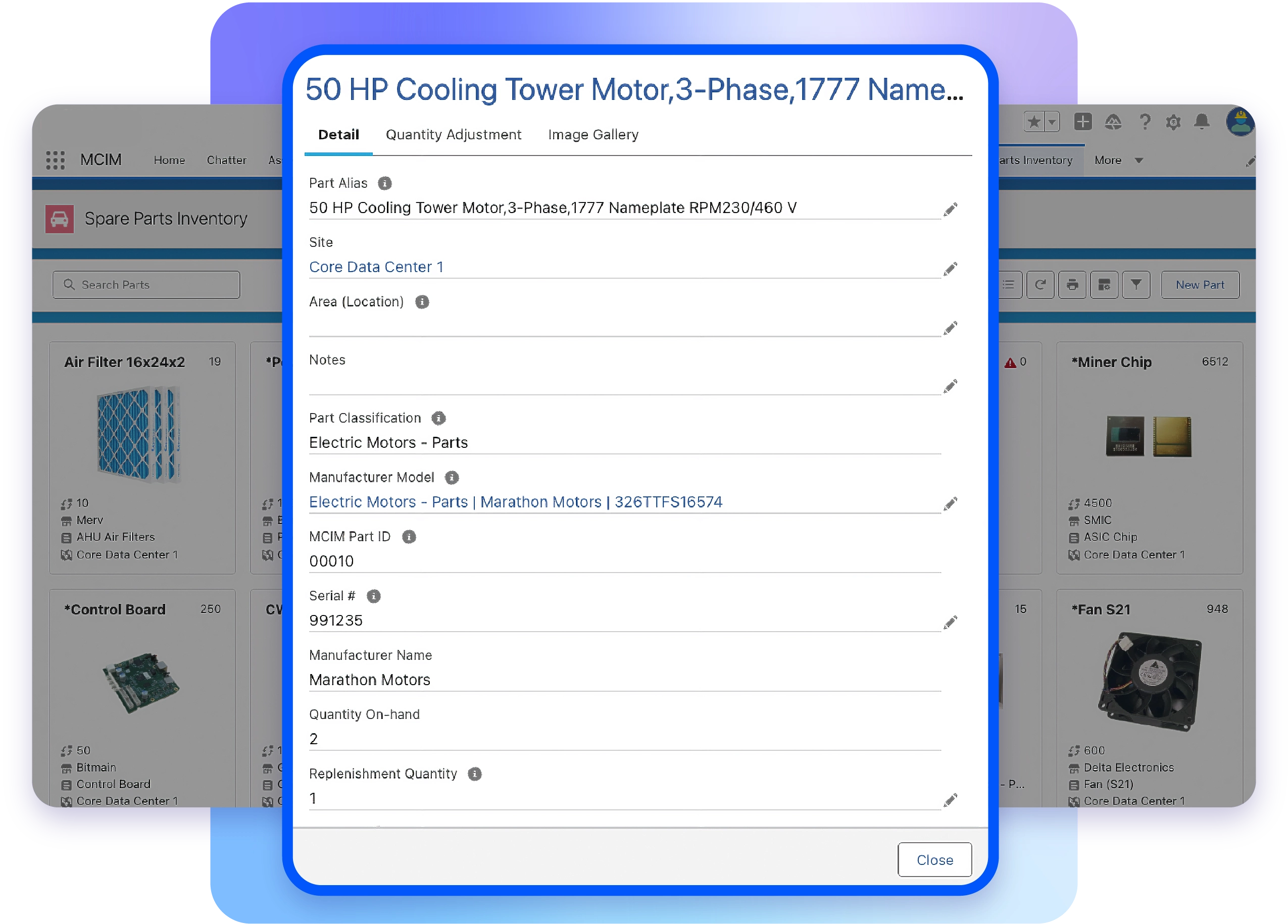

Spare Parts and Consumables

Track spare parts usage, costs, and SLA impacts across your critical facilities.

Learn moreMission-critical facilities have never been more critical, but most tools can’t handle the entirety of their needs. MCIM replaces disparate tools and disconnected workflows, providing a single platform for greater ROI.

Bring order, insight, and control to every asset, from a single site to your entire global portfolio. MCIM’s EAM module unites compliance, condition tracking, and capital planning into one intelligent workflow.

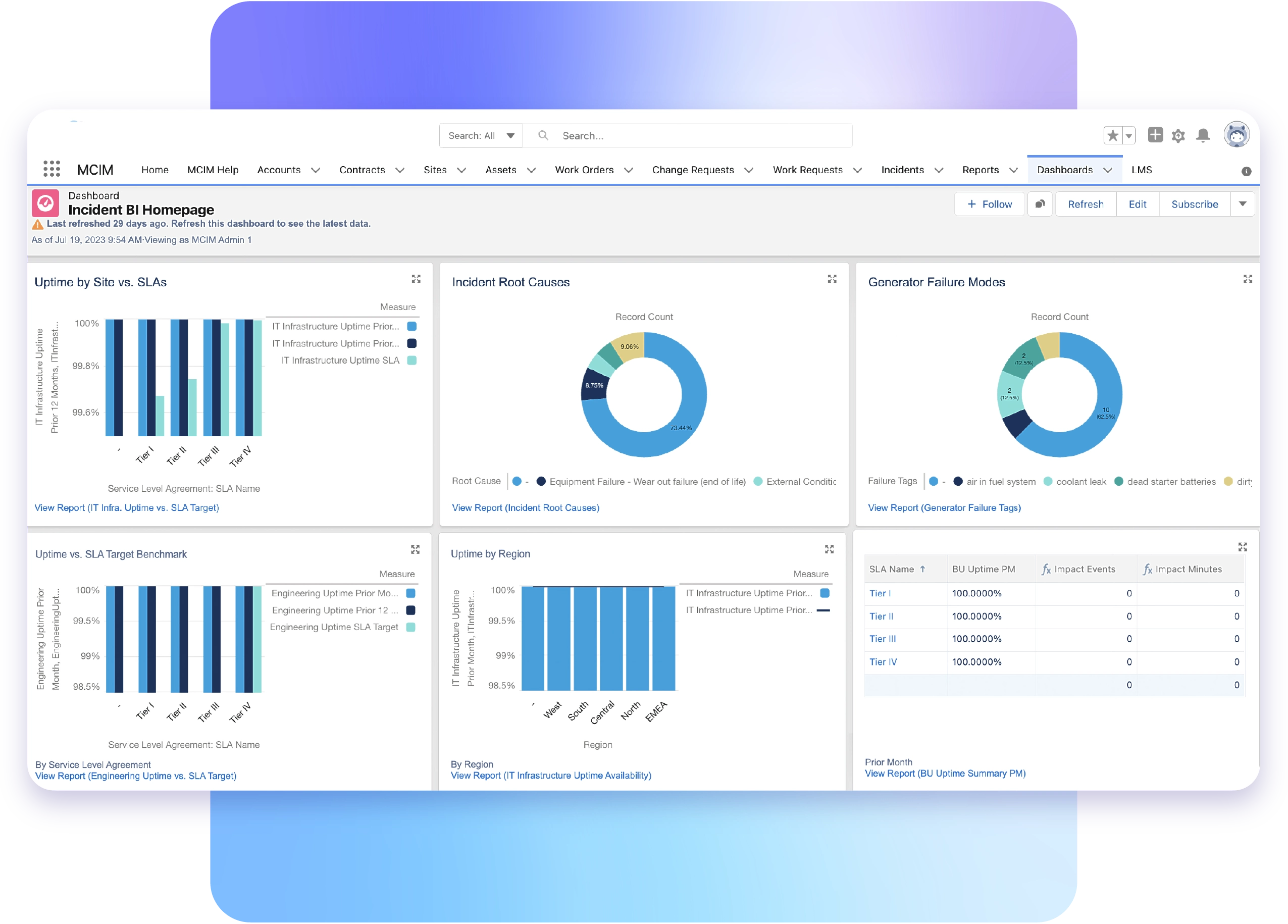

Prevent downtime before it starts. MCIM’s Incident Management module standardizes capture, root cause analysis, and corrective action across every site, ensuring clean data, faster response, and measurable reliability improvements.

Stop relying on clipboards and inconsistent logs. MCIM’s Rounds Monitoring module digitizes data collection, validates readings in real time, and flags anomalies before they become incidents. Get the visibility and confidence you need to act faster across every site.

Eliminate paper trails and preventable errors with MCIM’s Intelligent CMMS capabilities, purpose-built for mission-critical environments. Connect maintenance planning, task execution, and automated reporting in one clean workflow, improving uptime, compliance, and efficiency.

Replace manual checklists with standardized, data-driven evaluations. MCIM’s Assessments module captures consistent insights across every site, revealing risks, benchmarking performance, and empowering smarter, faster decisions.

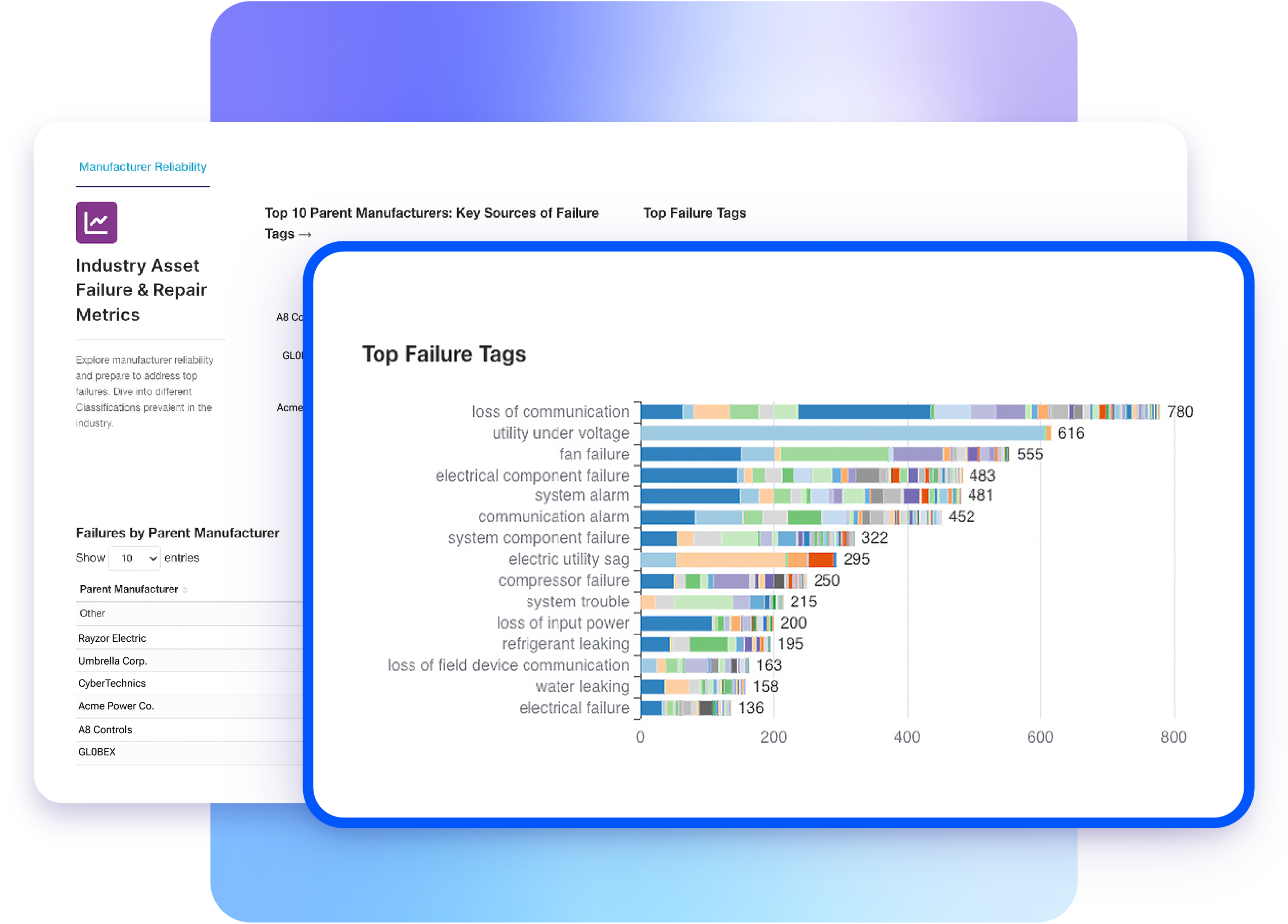

MCIM’s industry-first benchmarking engine lets you compare equipment performance in real time across over one million data center-specific assets worldwide. Make confident decisions about maintenance, procurement, and replacement backed by clean data and proven peer insights.

Enhance platform capabilities with deeper insights, automation, and efficiency, reducing downtime and optimizing resources.

Track spare parts usage, costs, and SLA impacts across your critical facilities.

Learn more

Enhance visibility, standardize reporting, and accelerate insights.

Learn more

Digitize safety compliance and permitting for greater efficiency and control.

Learn more

Provide colocation customers with automated tools and operational insights.

Learn more

A solid asset management system is crucial for ensuring operational continuity and minimizing downtime. See why a Tier III data center turned to MCIM for a transformative solution.

Book a demo today to see how you can make every data center stronger.

Centralize data, ensure compliance, and optimize performance across your portfolio.

Streamline incident management for faster resolution and reduced downtime.

Optimize maintenance and maximize uptime with Intelligent CMMS.

Elevate your facility monitoring with smart rounds management.

Optimize facility performance with proactive assessments.

Benchmark your assets against industry data for strategic decision-making.

Centralize parts data to prevent shortages, improve forecasting, and stay fully stocked.

Digitize protocols to enhance safety and streamline mission-critical operations.

Empower customers with real-time visibility and seamless communication.

Enhance visibility, standardize reporting, and accelerate insights.

Elevate critical operations with clean data, unified intelligence, and predictive analytics.

Optimize facility management with efficient processes, maintenance, and real-time insights.

Uncover cost-saving opportunities with insight into asset utilization and operating costs.

Turns fragmented asset planning into a strategic, data-driven process for maximum ROI.

Track equipment performance, cut waste, and maximize efficiency.

Automate reporting and gain real-time insights to help staff focus on high-value tasks.

Proactively prevent disruptions, reduce risk, and ensure the best equipment choices.

Gain insights to measure impact, reduce emissions, and drive sustainable performance.

Unify data and automate workflows to boost productivity and protect uptime.

Read our latest company, industry, and platform news.

Get into the details with deep insights, data, and research articles.

See how clients across a wide range of industries drive results with MCIM.

Find out where we’ll be next, like trade shows and industry events.

Find guides, checklists, white papers, and more to help you run your data center.

Calculate the return on investment you could experience using the MCIM platform.