Reduce Downtime and Improve Resource Allocation

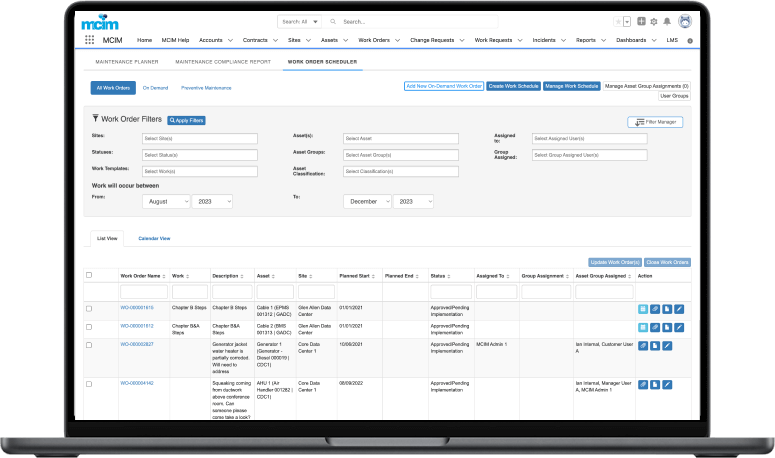

☑️ Automated Work Order Scheduling Ensure timely maintenance with recurring schedules and automated task assignments.

☑️ Customizable Workflow Approvals: Tailor maintenance approval processes to match organizational needs and compliance standards.

☑️ Preventive & Predictive Maintenance: Shift from reactive fixes to proactive asset care, reducing emergency repairs and unplanned downtime.

⭐ Enhance Workforce Efficiency: Optimize technician scheduling and labor allocation to complete tasks faster and minimize delays.

Standardize Procedures and Maintain Audit-Ready Records

☑️ Version-Controlled SOPs & Maintenance Logs: Maintain up-to-date maintenance procedures, ensuring compliance with industry standards.

☑️ Mobile Execution & Real-Time Updates: Allow field teams to log work orders, capture maintenance data, and update tasks from any location.

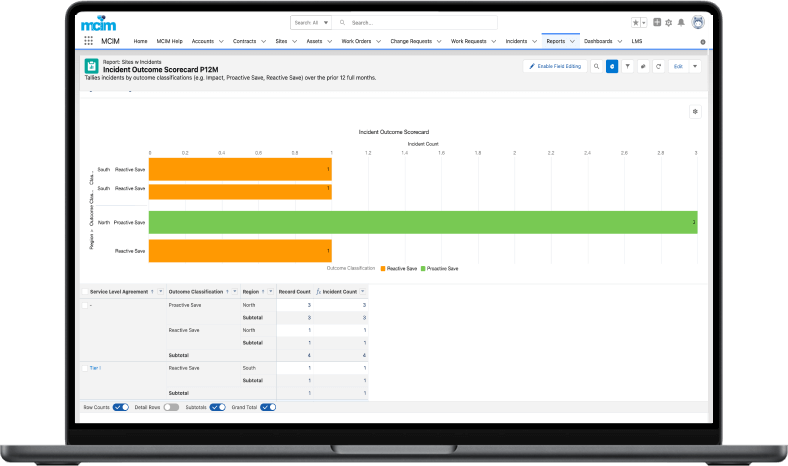

☑️ Exception Tracking & Risk Alerts: Flag and address maintenance exceptions before they escalate into costly failures.

⭐ Eliminate Manual Reporting Hassles: Automate compliance tracking and reporting for seamless audits and regulatory adherence.

Scalable, Secure, and Designed for Data-Driven Maintenance Management

☑️ Integrated Spare Parts & Inventory Management: Ensure critical replacement parts are available when needed, reducing equipment downtime.

☑️ Labor & Cost Tracking: Monitor work order completion rates, track technician performance, and optimize maintenance budgets.

☑️ Seamless Integration with Asset & Incident Management: Link maintenance data to asset health and failure tracking for comprehensive operational insights.

⭐ Reduce Operational Disruptions: Utilize predictive analytics to prevent failures and extend asset lifespans, improving overall facility reliability.

MCIM’s maintenance management module eliminates manual inefficiencies, ensuring optimized work order execution and continuous asset performance.